I wanted to know how 3D printers will impact corporations, so I took a class.

I find value in hands-on field research

In the aim for further understanding the impact of the empowered customers to corporations, I took a class on 3D printing at my local Techshop, where regular folks can learn cutting edge skills. Previously. this spring, I visited Maker Faire where thousands of people who want to make their own products (rather than buy them from corporations) assemble to share, hone, and show off their skills. The big winner was the large pavilion of 3D printers, which I shared my findings. I’m also living the collaborative economy movement, I’ve reduced buying physical goods, and prefer to rent or get on-demand, and even allowed a stranger drive off in my family car. In all these examples, I’m trying to live and experience to understand, rather than just be a casual observer.

I see three movements: social business > collaborative economy > makers movement

I’ve found that there are three major movements in our direct view, some more obvious than others. The first is the social media movement. where the sharing of ideas and media have democratized information, spreading power to the crowd, to date most companies have joined in from marketing and customer care departments, but struggle to go further. The second movement is the collaborative economy, where people can share goods and services directly with each other –rather than buy them from corporations. The third movement, approaching quickly on the horizon, is the maker movement, where people can make their own goods and products, rather than buy at all. If you look carefully, the disruption increases in each movement, with some folks building their own cars.

What I learned: These early days show great future

To couch my experience, I only took the 101 class, and I have much more to learn, but here’s my early experience. I attended this class with Vivian Wang, Kenny Lauer, and Korman R.

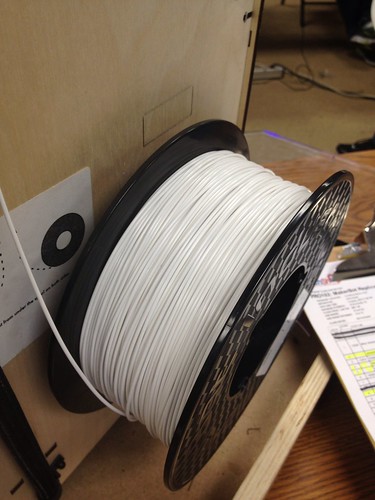

- 3D printers show great promise. These technologies have the ability to enable production and manufacturing anywhere, radically changing business logistics, power, and empowering those who use them. Some of the materials we saw printed were plastics, and biodegradable corn-based materials. There was even water-soluable materials that could be used as ‘filler’ to hold the model up while it was being printed. At a recent meeting of the minds at Stanford, we explored how these 3D printers could emerge at UPS locations, retail outlets, Kinko’s and then eventually move into garages, homes, and kitchens.

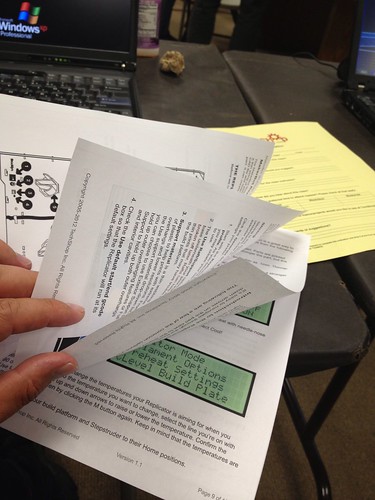

- My limited experience concluded a clunky experience. Maybe I’m just new to it, not techny enough, or didn’t have enough experience, but I found the overall setup of the 3D printing complicated and klunky. There were 12 pages of instructions we went through, including learning to use the unforgiving software, finding files online to use, configuring the printer, heating the plate, affixing the spool, using an SD card, and managing a build time that could be over an hour. I’m no luddite, but at the same time, I don’t want to over-hype this technology, it requires some learning, skill, craft as a proper hobbyist should. Visions of playing with dot matrix computers in elementary school came flooding back.

- They are on path to advance to advance to become consumer-ready. To go mainstream, this needs to move out of the hobbyist or prosumer hands and get into homes, this will require easy plug-and-play setup, access to files, ability to quickly manipulate and rapidly produce in a safe way. While Staples already sells an entry level 3D printer called “The Cube” it’s not clear how successful it is, with a single review (and Amazon only has 5 reviews). I imagine future versions are cloud based, with a thin client on a laptop, and a large easy to access marketplace of designs and a service marketplace of people who can help you customize for a fee.

What it means to Corporations: Even more opportunities and disruptions ahead

I’m meeting with some of the experts at Autodesk soon, who’ll show me some of the advanced setups, but in my limited experience, I think there’s still a ways to go for this new technology set.

- 3D printings on horizon, but not dominating… yet. While maker movements have been around since people were in our earliers villages (with surnames like “Smith, Potter, Tanner”) these early skills gave way to mechanization of the industrial revolution. Now, with communities like Etsy, Quirky, and Shapeways who provide 3D printed items, there’s an opportunity to grow new businesses of highly personalized, on-demand products.

- Those who use these tools will have more power than others. Just as we saw corporations adopt the internet to regain communication power, and then adopt social media to regain reputation control, corporations will also need to integrate these on-demand production machines at work, at partner locations like retailers, and at homes. Brand that move in now can establish an ecosystem to ensure their designs are properly used, perhaps with license fees, a community and marketplace of designers who build together, and those that provide higher quality materials.

- Physical good companies that don’t get involved risk disruption. These machines often have 3D scanners that can scan any item, then replicate it with the printer, just like a facsimile machine did with paper. In the hands of massive production, these copied designs can quickly be shared online in new napster-like networks, enabling the crowd to build on top of them, improve them –without the corporation involved. Companies that make simple physical goods must learn how to enable this technology before it gets ahead of them.

Select photos from the class:

Above: First things first, getting to know the 12 page instruction sheet, I took copious notes to learn the new terms, phrases, file types, software applications, and printer units.

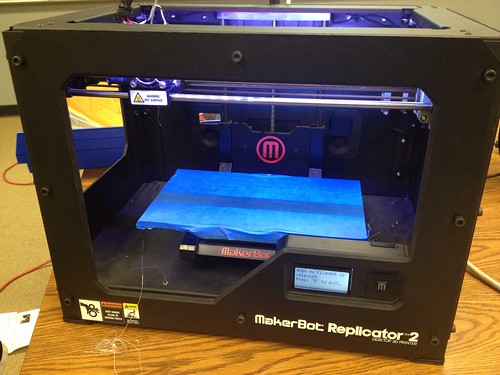

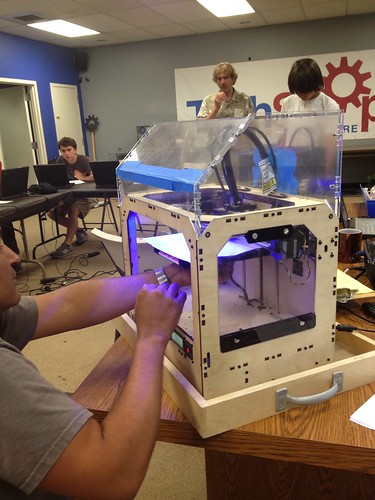

Above: My view, in class. Each student had an IBM laptop, and in the center was a Makerbot Replicator 2

Above: Behold the beautiful Makerbot Replicator 2, the center build plate is heated, and colors of printer indicate status, heat, and more.

Above: ReplicatorG software with a pre-loaded STL file (mine was a cookie cutter, in the shape of a christmas tree)

Above: Each time the printer is turned on, and ideally before each item is used, you should adjust the build plate to ensure it’s level with 3-4 small knobs

Above: The Replicator G software had many configuration fields for printing type, time, speed, quality, support and more. For a novice user, a class, and lots of experimentation is required for each print.

Above: A spool of 3D printing filament, this one, I believe is PLA, which is biodegradable as it’s corn-based, pricing ranges in $30 price area. The plastic material is ABS, which can be more durable but less flexible. Each material prints with different attributes: from density, shrinkage, heat resistance, and stability. They come in thousands of colors, including glow-in-the-dark.

Above: A small jar in the clever shape of the TechShop logo was on display in the front lobby

Above: A 3-D printed whistle (with a floating pea inside that was inserted mid-print). Below the whistle is ‘support’ which can be used to print complex structure and then is removed post-print with a knife, and a ‘raft’ which stabilizes advanced prints.

Above: On display, an advanced model of a small intricate artifact was featured in the front of the shop.

Above: Look closely the cross-hatch ‘Infill’ determines the quantity of the interior material used in this batwing, this one was set at 30%, I believe. These took about 18 minutes to print, but the expert instructor had it optimized, some builds could take hours.

I hope you enjoyed learning about my experience as much as I enjoyed sharing it. It’s safe to say, I’m no expert, but will continue this journey of knowledge and wanted to share with you my early findings in my continued field research as the crowd continues to become more empowered. Love to hear your questions, thoughts, and comments below. I look forward to returning to TechShop to continue to learning and experiencing more.

Jeremiah, 3D printing capabilities have an ability to astound that in and of itself is disruptive. As the technology progresses and becomes more mainstream, it is likely to disrupt another key area: intellectual property. While it may damage the concept of monopoly, it may also usher in an era of ingenuity and creativity, the likes of which we have not seen since the beginning of the industrial era. Intellectual property holders will face challenges from the “making economy” far more significant than those they will face from the “collaborative economy.” If we, as a society, continue to believe that we need some limited monopoly to spur innovation, our laws will need to adapt in ways that we cannot yet predict. Some industry members may rejoice in the potential for breakdown of monopoly. A more fruitful response may be for industry members to work together to research and suggest best practices so that brands can continue to thrive in our capitalist system while users can avail themselves of the freedoms of a “maker economy.”

These are interesting developments indeed, and I see great potential for 3D printing as well. Imagine a spare part for the ISS printed at location in space? What worries me a bit though, is that the technique can easily be used to reproduce unwanted goods, such as weapons, without limitations. Like any data on the internet, you cannot destroy undesirable designs and prevent them from being spread.

@Kyle-Beth, as far as brand monopoly is concerned, we might want to look into iTunes-like solutions, with highly convenient design stores and attractive prices. Some piracy will always exist, but like Jeremiah states, businesses will have to search for new business models to keep up with the developments.

Hi Jeremiah, I heard about the ISS plans before and sure got the news about the printed gun, hence my worry. Time will tell how this technology will be implemented and how it will influence our lives and businesses. Somehow it reminds me of the discussions about cloning and stem cell research…

What I love is the fact that I can learn to design, but I can use an online 3D printing service so i don’t have to futz with the different types of printers and work out their idiosyncrasies. I just don’t have time for that at this point in my life.

Yes Jochem, some piracy is inevitable, and businesses will not just be searching for new business models. They will also need new enforcement models.